Before I started working in the engineering side of Architectural Millwork and Custom Cabinets – I worked out on the shop floor. Early in my career, I spent about five years working for a company that dealt almost exclusively in Commercial Casework. I spent the bulk of my time pulling Plastic Laminate from Job Bins and applying it to case parts.

I didn’t realize it at the time but I was routinely working with a Millwork Finish Schedule. Without it, I’m not sure how I would have been able to do my job effectively.

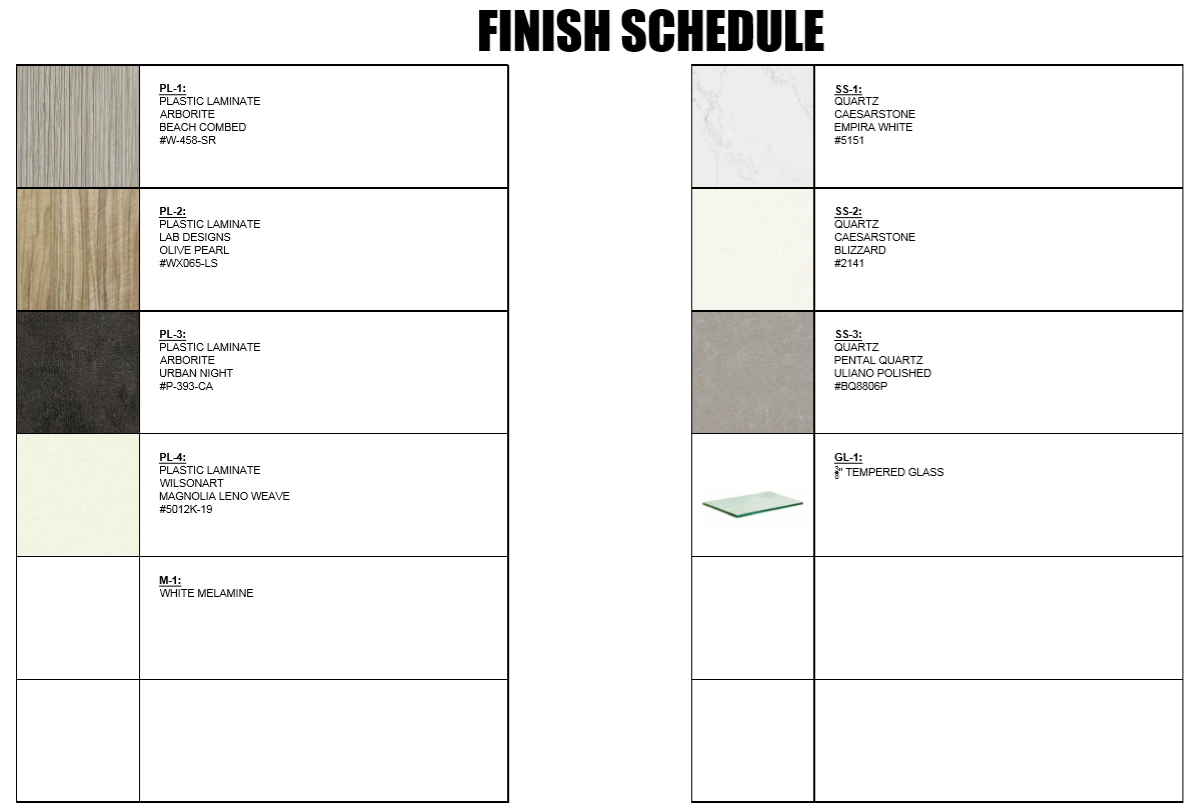

As a Draftsman, creating and utilizing a Millwork Finish Schedule is a critical component of any Quality Shop Drawing. Properly utilizing this schedule will drastically reduce costly mistakes and ensures that your customer will receive their desired Wood Species, Color, or Specialty Finish.

In this article we will take a look at what a Millwork Finish Schedule is and how to create one for your project.

What is a Finish Schedule

A Finish Schedule is simply a detailed listing of all Finishes used throughout a given project. This will include things such as Plastic Laminate Color Selections, Wood Species and Cut, and Specialty Finish Options – such as Reproduction Chipped Paint, Hand Tooling, Antiquing, Glazing, or Wire Brushing.

The Finish Schedule will detail each option and a Finish Designation will be assigned. This designation acts as shorthand so that each and every drawing in the set does not require a breakdown of the specific finish. For example, something like a Wilsonart Cosmic Strandz Plastic Laminate may simply be referred to as PL-1.

The beauty of this system is that it is easily modified. If an Architect, Designer, or Homeowner decides that that they aren’t happy with a particular finish – it will only need to be updated on the Finish Schedule. All of the existing designations can remain the same on your shop drawings – which saves a great deal of updating.

Finish Schedule for Commercial Applications

When working on a Commercial Project – the process of creating a Millwork Finish Schedule is very simple. I say this because in most cases the Architect will release a Finish Schedule as part of their Issued for Construction Drawings. Your Millwork Shop Drawings will simply incorporate the Architect’s schedule with some modifications.

The first modification that will need to be made is omitting all of the information that is not applicable to your scope of work. For instance, the Cabinet Shop will most likely not need the Carpet Information, Resilient Base Selection, or Wall and Ceiling Paint Colors – among other things.

What you will need is the selection for Plastic Laminate, Wood, Stone, and Solid Surface. You may also need to research and add PVC Edgeband colors to match the Plastic Laminate Selections.

Finish Schedule for Residential Applications

When working on a Residential Project, the process of developing a Millwork Finish Schedule can be a little tricky. In this scenario, the Homeowner may be working with an Interior Designer that has’t developed a comprehensive Finish Schedule. Instead, you may need to work with a simplified Finish Schedule and reference approved physical samples.

For instance – Stain Grade Kitchens may have a Perimeter that is one Wood Species and Color while the Island is another Species and Color. Both the Perimeter and Island may even have accent molding that is yet another Species and Color.

All of these Species and Color options will need to be cataloged on your Finish Schedule to reduce confusion during the manufacturing process.

Creating your Millwork Finish Schedule

Now that we understand what a Finish Schedule is we can begin building our own. Here at Superior Shop Drawings, we like to add in a layer of redundancy and incorporate a image of the actual finish. By doing this, we feel that it sends up a red flag if for some reason the image doesn’t look like the sample chip.

Start out by creating a Chart. Each portion of the chart should be large enough that it includes the following information for each Finish Designation. Once the chart is created with all of the appropriate designations, it is simply a matter of going through and filling in the fields.

Plastic Laminate, Stone, or Solid Surface

- Designation

- Manufacturer

- Color Name

- Color Number and Finish Code

- Notes

Solid Wood and Wood Veneer

- Designation

- Wood Species

- Cut

- Finish

- Notes

As you can see, there isn’t a lot involved to creating a Millwork Finish Schedule – provided you have the necessary information. From time to time you will come across a project that hasn’t had color selections finalized. In that case, simply do your best and include a note to Please Specify.

- Millwork Shop Drawings: Training Survey - May 5, 2024

- Optimize Your Shop Drawings: Exploring the Power of theAutoCAD DimSpace Command - December 5, 2023

- The 4 Grades of Kitchen Cabinets: What Does It All Mean? - November 28, 2023