When I was a kid, Woodworking was a hobby and a career for many of the men in my family. Aside from the knowledge I gained from spending time in basement and garage workshops – I was a sucker for watching Norm Abram work his magic on the New Yankee Workshop.

When I reached High School, I knew immediately that I wanted to be a part of the Cabinetmaking Program to expand my knowledge. One of the very first projects that I was given was a simple box. “Alright class, here are the parts you will need to make your box. Each corner is to have a different joint and they all need to be cut by hand”

Among the joints I chose for my box was the Mortise and Tenon. With a backsaw, mallet, and chisel – I got down to business. While my box wasn’t the prettiest thing I made that semester, it taught me a great deal about joinery and how to work them without machinery.

A Mortise and Tenon is a common Woodworking Joint that attaches two pieces together – typically at a ninety-degree angle. The joint is made up of two parts. The mortise is the female joint, a slot cut into the wood. The Tenon is the male end of the joint, which fits into the mortise.

In this Blog Post we will look at a few common variations of the Mortise and Tenon Joint. As you will see, this is a relatively simple joint that will add great strength to your next project.

Anatomy of the Joint

The Mortise and Tenon Joint boils down to two components – the mortise and the tenon. The mortise is the slot (female component), which is made up of four walls. The size of the mortise is often determined by the size of the chisel or router bit that will be cutting. For Framed Cabinet Construction, this is typically 1/3 of the frame thickness (1/4″ on a 3/4″ Thick Frame).

The Tenon is made up of Shoulders and Cheeks (male component) and should fit snugly into the mortise. When properly sized, this joint should fit together with minimal effort and not fall apart when picked up.

Types of Mortise and Tenon Joints

The Mortise and Tenon is a simple joint in premise. Variations on the joint can range from simple (Through Mortise and Tenon) to intricate (Interlocking Mortise and Tenon). In this Blog Post, we are going to take a look at the four most common variations of the Mortise and Tenon.

Through Mortise and Tenon

The Through Mortise and Tenon is exactly what it sounds like. The mortise passes through the part entirely and becomes exposed. The tenon fits into the mortise and is either cut flush or left long. Generally, if the tenon is left long it will utilize a wedge to lock it into place.

Blind Mortise and Tenon

The Blind Mortise and Tenon is designed in such a way that the joint becomes invisible once assembled. The mortise stops short and does not pass through the part. The tenon will also but cut short so that it stops just shy of bottoming out in the mortise. While this joint is a little more involved than the Through Mortise and Tenon, it is a great way to add strength while concealing the joinery.

Pegged Mortise and Tenon

The Pegged Mortise and Tenon Joint can be any variation of those outlined above. The major difference with this joint is that it utilizes pegs to lock the joint in place.

After the joint is assembled – a secondary mortise will be cut through the joint. This second mortise will pass through both the original mortise and the tenon. A peg (either round or square) will then be inserted which locks the joint together. Often times these pegs will be a design element and will remain exposed.

Floating Tenon

The Floating Tenon is a variation on the Mortise and Tenon which utilizes two mortises. The Tenon, rather than being attached to one end, is an independent component that will be slipped between the pieces and glued into place.

I have installed countless Floating Tenons into 5-Piece Cabinet Doors – primarily on Cope & Stick Doors. The Floating Tenon simplifies the door construction process and adds a great deal of strength to the door.

We’re Happy to Help

We hope you now understand the Mortise and Tenon Joint and how to utilize it in your next project. As always, if you have any questions or want another topic covered here on Superior Shop Drawings – drop us a line in the comment section below!

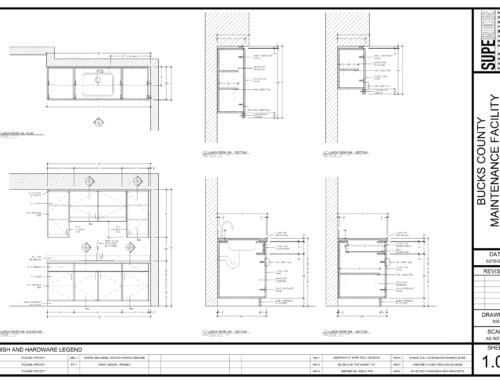

Work with Superior Shop Drawings

Are you an Architectural Millwork Shop or a Custom Cabinetmaker in need of Shop Drawings? Steve and Walt have been in the Cabinet Industry for over 20 years and specialize in creating Shop Drawings for Commercial and Residential applications using AutoCAD. We are happy to discuss your next project and provide a free quote.

- Millwork Shop Drawings: Training Survey - May 5, 2024

- Optimize Your Shop Drawings: Exploring the Power of theAutoCAD DimSpace Command - December 5, 2023

- The 4 Grades of Kitchen Cabinets: What Does It All Mean? - November 28, 2023